**Introduction:**

With the rapid development of new energy sources, lithium-ion batteries are widely used in various fields. However, in low-temperature environments, lithium-ion batteries face a series of performance challenges, including a decrease in discharge capacity, an increase in internal resistance, and a reduction in charging and discharging efficiency. This article will delve into the issues of lithium-ion batteries in low-temperature conditions and introduce some strategies, with a particular focus on the research and development of lithium-ion battery preheating technology.

**I. Impact of Low Battery Temperature on Battery Performance**

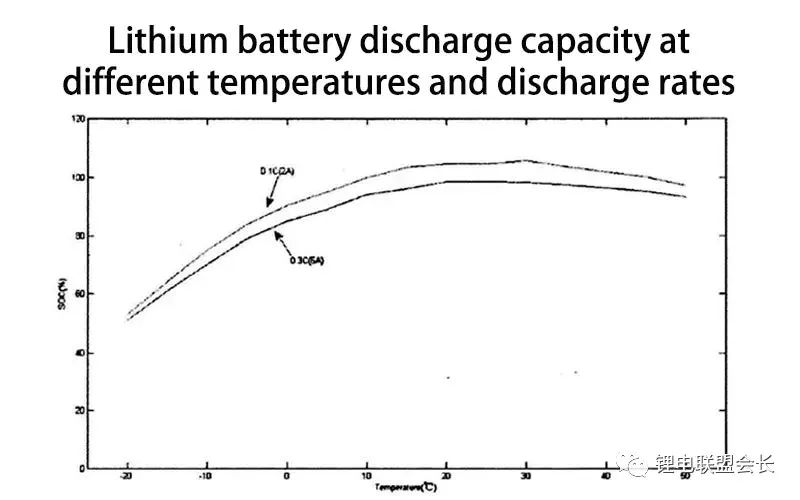

1. **Decrease in Battery Discharge Capacity:**

Battery capacity, one of the most crucial parameters, significantly decreases in low-temperature environments. Observing the temperature-capacity curve reveals that at -20°C, the capacity is only about 60% of that at 15°C. This is primarily due to the reduction in the activity of the positive electrode material, slowing down the movement of lithium ions and resulting in decreased capacity.

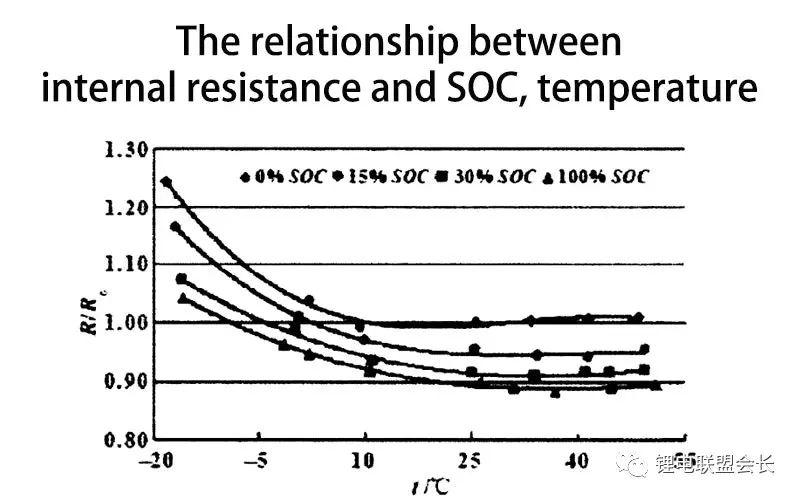

2. **Increase in Internal Resistance:**

There is a clear relationship between battery internal resistance and temperature, with a substantial increase in internal resistance at low temperatures. This is because the diffusion and movement ability of charged ions in the positive and negative electrode materials decreases, leading to an increase in internal resistance. The formation of a passivation film between the electrode and electrolyte hinders the free movement of ions.

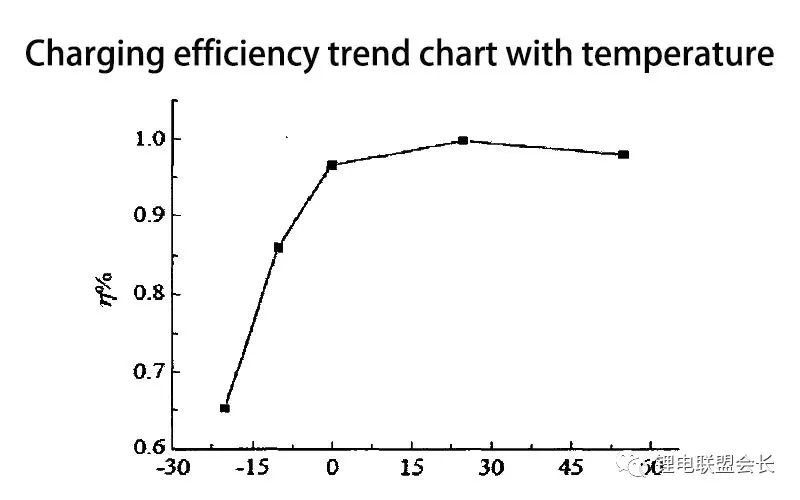

3. **Reduced Charging and Discharging Efficiency:**

Under low battery temperature conditions, charging efficiency is significantly affected. At -20°C, the charging efficiency is only 65% of that at 15°C. This is due to changes in electrochemical performance causing a considerable amount of electrical energy to be consumed as heat in internal resistance, thereby reducing charging efficiency.

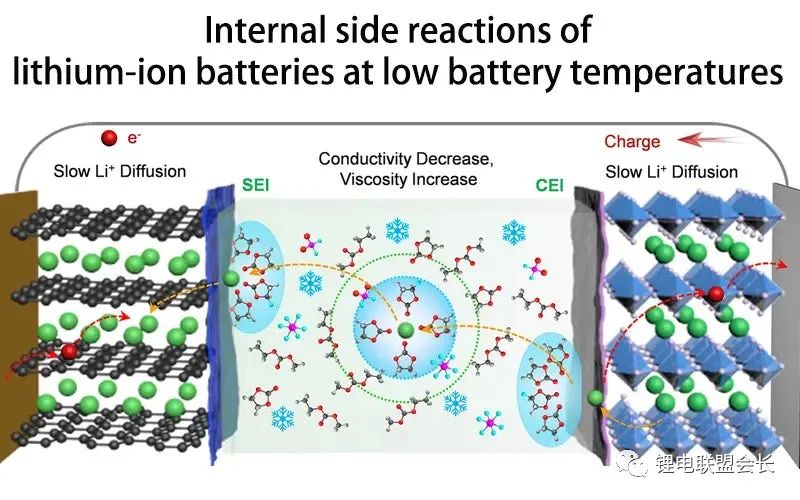

**II. Secondary Reactions Inside Lithium-ion Batteries at Low Temperatures**

In addition to performance degradation, lithium-ion batteries undergo various secondary reactions at low temperatures, leading to a decline in battery capacity and deterioration in performance. These reactions mainly occur between lithium ions and the electrolyte, forming irreversible reactions.

1. **Negative Electrode Reaction:**

The potential of the negative electrode material is much lower than that of the positive electrode material, resulting in irreversible reactions occurring at the negative electrode, forming the problematic Solid Electrolyte Interface (SEI) film. Cracks in the SEI film provide a direct contact channel between the electrolyte and electrode, causing continuous internal reactions and performance degradation.

2. **Positive Electrode Reaction:**

The reduced activity of the positive electrode material hinders the diffusion and movement of lithium ions at the positive electrode. Continuous cycling causes electrode expansion and contraction, leading to SEI film rupture and further affecting battery performance.

**III. Research and Development of Lithium-ion Battery Low-Temperature Preheating Technology**

In the face of the challenges posed by lithium-ion batteries in low-temperature environments, technicians have proposed strategies such as charging and preheating to improve battery discharge capacity and long-term lifespan.

1. **Preheating Methods:**

Preheating methods can be categorized into external heating and internal heating. Compared to external heating, internal heating avoids long-distance heat conduction and the formation of local hotspots, providing more uniform heating of the battery, thus improving heating efficiency.

2. **Internal Alternating Current (AC) Preheating Approach:**

Research focuses on heating speed and efficiency, with a need to prevent secondary reactions such as lithium deposition during preheating. The Battery Management System (BMS) needs to real-time estimate and control the conditions for lithium deposition, requiring a model-based low-temperature control battery heating technology.

**Conclusion:**

In the context of the rapid development of lithium-ion batteries, addressing challenges in low-temperature environments becomes crucial. Through in-depth research into the impact on battery performance and continuous innovation in preheating technology, we can better address the performance issues of lithium-ion batteries in low-temperature environments, improve their reliability and lifespan, and drive the development of new energy applications.

If you're interested in learning more about our solar energy storage offerings, we encourage you to explore our product line. We offer a range of panels and battery that are designed for various applications and budgets, so you're sure to find the right solution for your needs.

Website:www.fgreenpv.com

Email:Info@fgreenpv.com

WhatsApp:+86 17311228539

Post time: Jan-02-2024