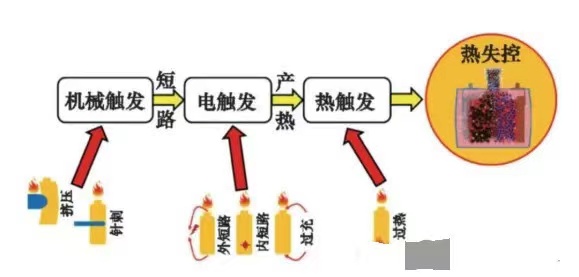

The fire risks in lithium battery energy storage systems mainly come from three aspects: out - of - control internal reactions in lithium batteries, external forces, and electrical equipment hazards. According to fire protection regulations, the battery placement area (hereinafter referred to as the battery compartment) and the area for high - and low - voltage electrical equipment (hereinafter referred to as the equipment compartment) should be designed separately.

1. Lithium Batteries: Internal Reaction Risks

Lithium batteries rely on chemical reactions for charging and discharging, which inevitably generate heat. If the heat generated exceeds the battery's heat dissipation capacity, the heat will accumulate, causing overheating.

Internal chemical reactions, such as the decomposition of the SEI membrane, electrolyte, and positive/negative electrodes, produce a large amount of heat and gas, leading to battery heating and swelling. This can trigger thermal runaway, causing the temperature to rise rapidly, igniting internal materials. The electrolyte decomposition releases flammable gases, which may explode when reaching a certain concentration and encountering an ignition source.

Moreover, the battery modules in energy storage systems connect multiple battery packs in series, increasing safety risks. If one battery fails and catches fire, it will affect surrounding batteries, expanding the fire scope.

2. External Force Factors

- Puncture Risks: Sharp objects (like metal debris or dropped tools) can puncture the battery. Although the casing provides some protection, strong impacts can pierce the metal shell and separator, causing internal short - circuits, rapid heat release, and thermal runaway.

- Mechanical Damage: During transportation or installation, severe squeezing or collision (e.g., vehicle vibration or improper handling) can deform the battery pack, damaging the internal electrode structure and causing short - circuits. Cracks in the casing may also leak flammable electrolytes, which can ignite when exposed to electrical sparks.

- Vibration Impact: Long - term high - frequency vibration can loosen connection components (e.g., cables and electrode contacts), increasing contact resistance and causing local overheating. Vibration also causes active materials to detach, worsening battery performance and thermal runaway risks.

3. Electrical Equipment Hazards

The stability and safety of electrical equipment in energy storage systems directly affect battery performance. The presence of high - voltage, high - current systems and numerous weak - current/communication systems can damage protective components, disabling safety functions and potentially causing fires.

Fire Safety Measures for Lithium Battery Energy Storage Systems

Lithium battery energy storage fire protection systems are designed for large - scale/distributed energy storage stations, mobile energy storage vehicles, and backup power stations, covering the entire power industry chain (generation, transmission, distribution, and consumption). Despite the advantages of lithium - based energy storage, the high reactivity of metallic lithium and frequent thermal runaway incidents in vehicles make fire safety a top priority. Here are key measures:

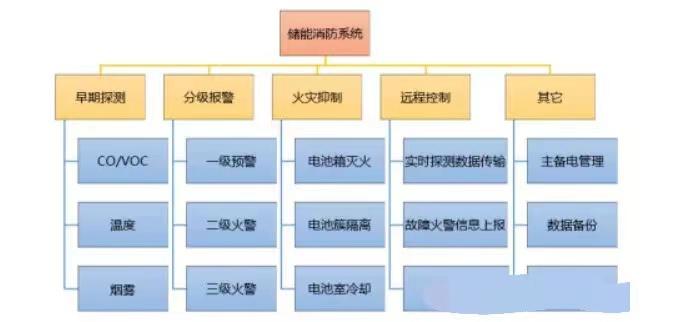

1. Fire Protection System

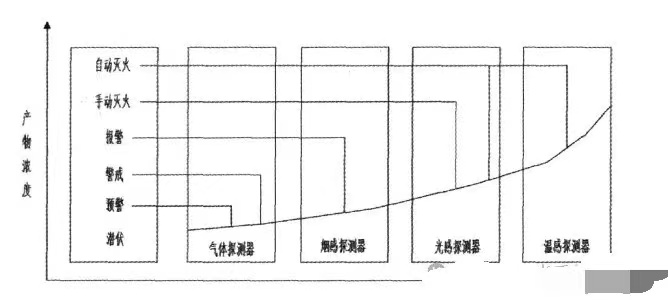

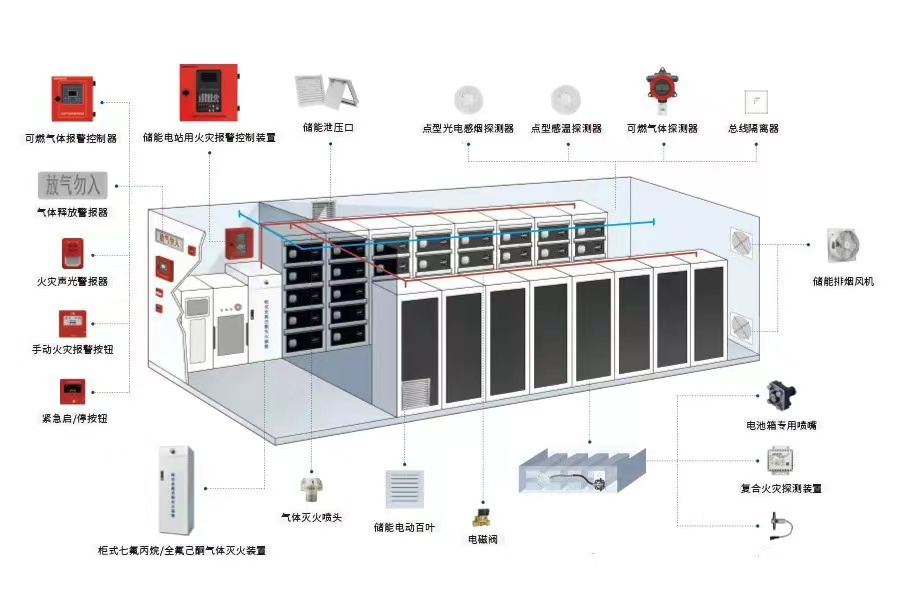

Lithium battery thermal runaway releases gases, energy, smoke, and even 明火 (open flames). Referencing standards like Code for Fire Protection Design of Thermal Power Plants and Substation Systems and Code for Design of Fire Alarm Systems, the battery compartment is isolated, and a dedicated fire protection system is installed, comprising:

-

Detection and Control: When gas composition in the battery compartment changes abnormally, devices like fire alarm controllers, composite detectors, and combustible gas sensors activate, monitoring hydrogen, VOCs, CO, smoke, and temperature. They trigger alarms, disconnect power, and send alerts to the control center. Emergency stop buttons, manual alarms, and audible - visual indicators provide on - site emergency controls.

-

Gas Fire Extinguishing: Equipment includes gas extinguishers, pipes, and nozzles, using physical methods (oxygen isolation) for rapid fire suppression:

- HFC - 227ea (Seven Fluoropropane): A colorless, odorless, non - conductive gas that suppresses chemical reactions. Stored as a liquid, it releases as a gas, leaving no residue and no damage to electrical equipment.

- Perfluorohexanone: A next - generation agent with high efficiency, rapidly vaporizing to isolate oxygen and cool the fire site.

- Liquid Nitrogen: An eco - friendly medium that cools physically and smothers fires by releasing nitrogen gas, which displaces oxygen.

2. Air Conditioning System

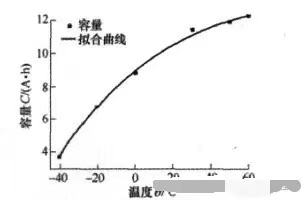

Lithium batteries generate continuous heat during charging/discharging. The optimal temperature for the battery compartment is 25℃, as low temperatures accelerate capacity decay, and high temperatures increase fire risks for electrical equipment and batteries.

3. Interlocking Devices

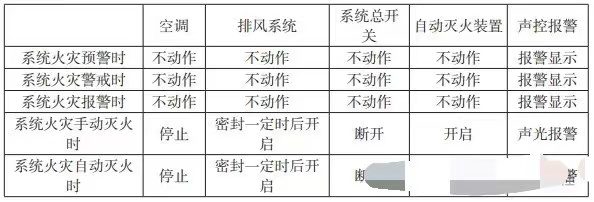

To prevent casualties from misoperations or emergencies, battery compartments are equipped with fire doors, exhaust systems, and external emergency stop buttons, interlocking with fire alarms, automatic extinguishers, and ventilation for multi - level safety.

4. Electrical Design

- Surge Protection: High - voltage circuits are fitted with lightning and surge protection devices to reduce risks from high voltage/current.

- Layout Planning: Mobile energy storage areas have at least 2 exits; above - ground systems reserve a 3.5m - wide fire lane, and underground systems have a 1.5m - wide escape route with fire facilities.

- Power Supply: Fire equipment uses independent power from the grid with fire - resistant cables to ensure reliability.

---

If you're interested in learning more about our solar energy storage offerings, we encourage you to explore our product line. We offer a range of panels and battery that are designed for various applications and budgets, so you're sure to find the right solution for your needs.

Website:www.fgreenpv.com

Email:Info@fgreenpv.com

WhatsApp:+86 17311228539

Post time: Jun-10-2025